(260).jpg)

(9).png)

Introduction:

The HL- WDI spot welder, is a kind of machine that used for the positive and corrects, treatment, the welding object is the steel silk of the diameter 0.2-1.2 mms, the stainless steel foil of the thickness 0.08-0.20 mms.

This machine also can used for the electric appliances, appearance and spread the feeling machine etc. welding of the small scaled spare parts.

This machine belongs to a kind of electric capacity sopt welder,solder belong to the electric resistance, since clips the piece of that two demand weld to compress tightly between the top and bottom electrode, because of in the whole back track the contact electric resistance of two piece is biggest, when switch on electricity, the electric voltage mainly declines in this part, so produce a great deal of calories, heating contiguous metals drive very soon slightly low melt the temperature in it.At this time under the machine pressure, piece was weld together.

The characteristics that keeps the ability type to order the machine of gets up the energy savings that obtains from the charged barbed wire net slowly, releasing an energy very soon at the moment that weld and then, to satisfy the energy of the big power that welding need.The process that keeps the ability and releases is the process that the electric capacity refresh and discharge, making use of the size that can controlled to adjust to press the machine to regulate to refresh the electric voltage, also be regulate to weld the energy of size, to adapt the demand of various welding.

Characteristics:

① Adopt microprocessor control system, reliable quality, and high control precision.

② Adopt digital display functional mode and power parameter, through membrane button to adjust the parameter, its convenient and concise.

③ Good in safety feature; it has overheating protection system, there’s indicator and alarm function with sub-pressure, overpressure and improper operation.

④ With the welding parameters memory function, when switch on, it will automatically show the same parameters as the last set, so there’s no need to adjust parameter again at the same condition.

⑤ Welding electrodes can be chosen with different combination, it’s suitable for the different weldment.

Parameter:

① Power supply: 220V, 50HZ or 110V, 60HZ

② Power: maximum current 20A

③ Transformer output power: 2000W, output voltage: 5V

④ Incorrect operation alarm: when operation condition don’t accord with SET mode, the display shows Error beep.

⑤ Security type: belongs classⅠ, type B

⑥ Transformer overheating protection: 85℃

⑦ Energy regulation: Spot welding (dxx)1~30 Braze welding (QXX)1~9

⑧ Dimensions of weldment: Ф0.2mm~1.8mm stainless steel wire

⑨ Fuse: Ф5×20mm, 20A

⑩ Environment conditions: temperature 5℃~40℃ Relative humidity ≤80%

⑪ Storage condition: temperature -10℃~55℃ Relative humidity ≤80%

Structure:

This machine front-panel left side has the light pillar type electric voltage indicator to used for the manifestation energy size, this machine still has the welding button, useding for the welding to move the control.This machine front-panel right side has to weld the power choice switch(common adjust) and powers to regulate the knob.( The nicety adjust) have the power switch and feet to step the switch electric outlet behind in the machine hull, when circumscribe the feet to step the switch, the feet step the control while can used for the welding.The machine hull still has the AC outlet of takes the fuse and take the light power switch behind.

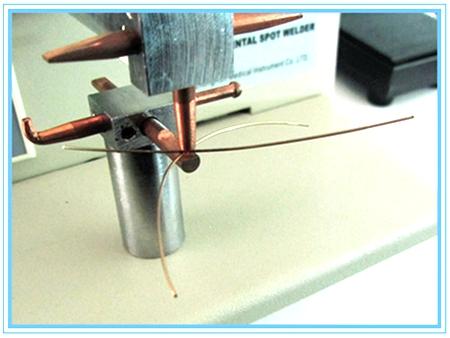

At the welding electrode arm have four electrodes, can the perpendicular revolve the choice, under there are also four electrodes on the welding electrode arm can the level revolve the choice, thus constituting to have another the demand to the electrode set of different combination, to adapt various different welding.For some special weldings, can also use to have no oxygen copper self-control electrode stick.The electrode revolve 90 degrees and all can position automatically each time.

Regulation:

1.Must use the list mutually three line power supplies, guarantee that the machine hull and the earths connect, to insure the safety.

2.The machine should place to face in the firm and dependable set up.

3.Use to communicate possibly steady press the power supply, since can guarantee the welding energy stability for regulate, can reduce this machine welding again as to it's the influence of his electric appliances.

4.Should press when electrode revolve clockwise revolve.

5.While regulating the energy, can at two electrode plus to turn on electricity the piece, press to move the welding to press button once, release the remaining electric power, to make to regulate the exactitude.

6.At weld the energy bigger or the welder piece get in touch with bad, produce while toing prevent°from weld of splash the thing burn human body.Operate the personnel must use the protection glasses and protection gloves.

7.When the machine occurrence break down, should contact the factory house or be fix by the professional personnel in time.

8.The machine uses to complete, should wipe clean after, place at dry well ventilated, have no causticity air of indoor

Packing List:

Power cable 1pc

The feet step the switch 1pc

Fuse 5 A 2pcs

Turn on electricity the piece 1pc

Warranty: One Year! Service: Whole Life!

(260).jpg)

(9).png)